Care, Respect and Commitment

Complying with the most demanding standards worldwide, putting at your disposal the highest efficiency that technology allows today, to obtain the maximum performance, adding to all this our values.

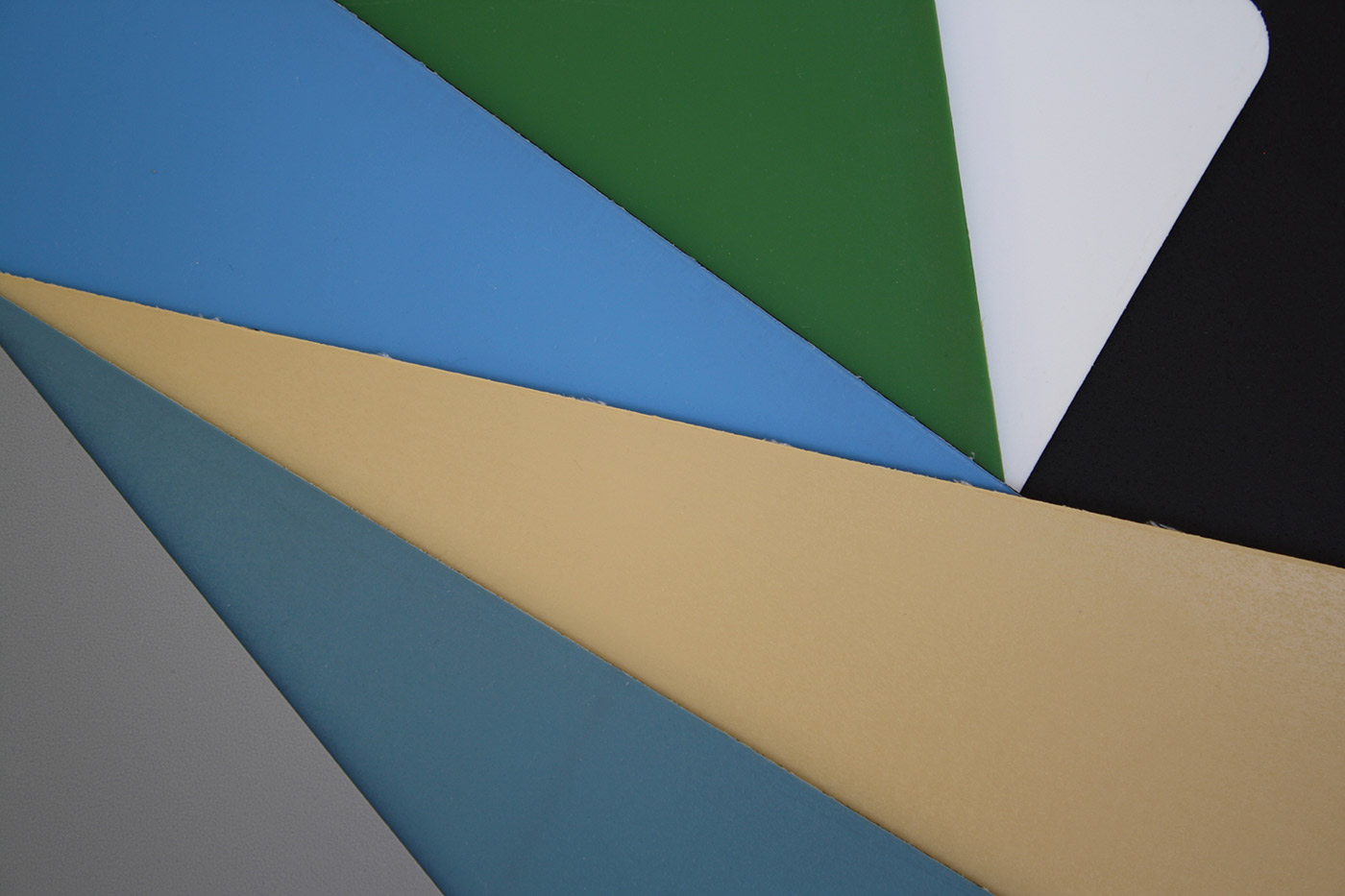

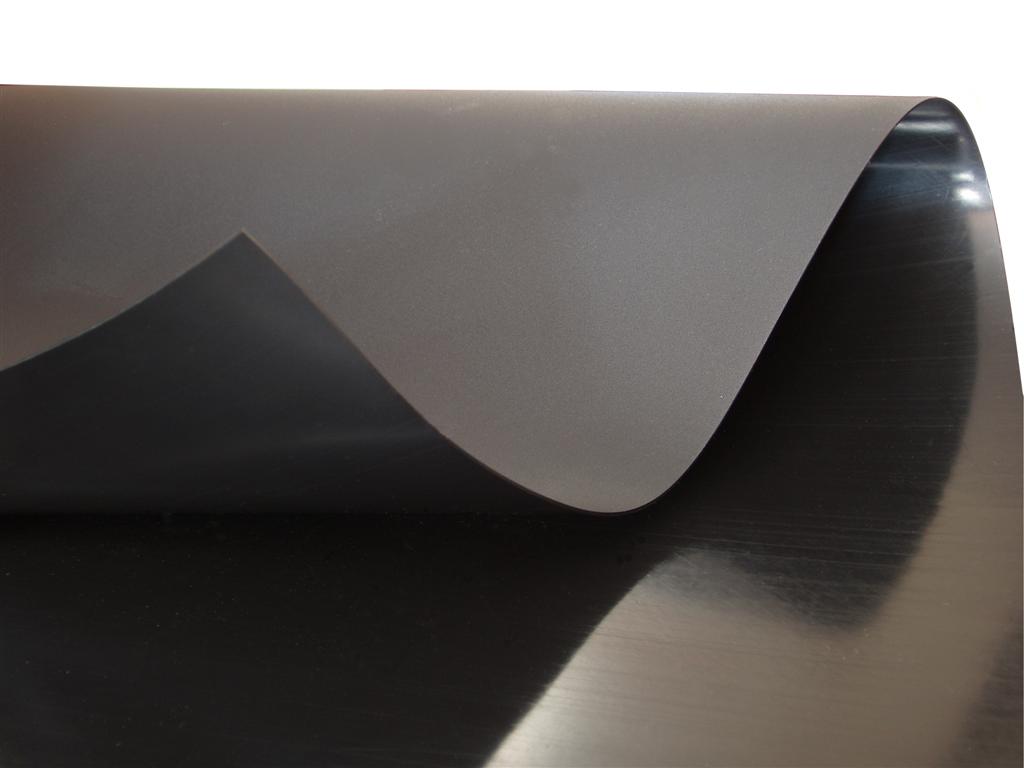

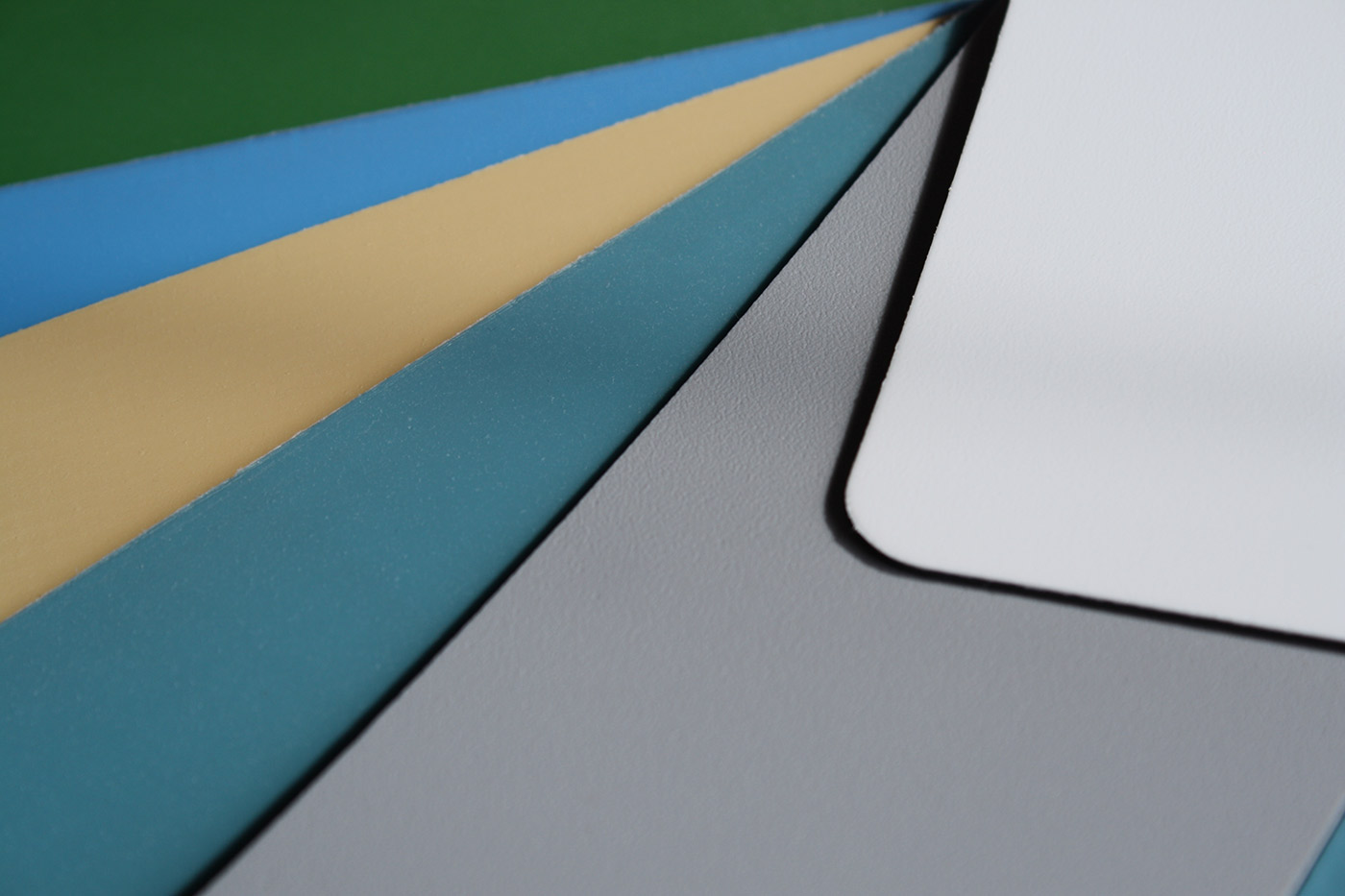

HDPE

Atarfil HDPE geomembranes offer exceptional resistance to chemicals and extreme conditions, ideal for applications in mining, waste management and water treatment. They guarantee durability and safety, complying with the highest international standards.

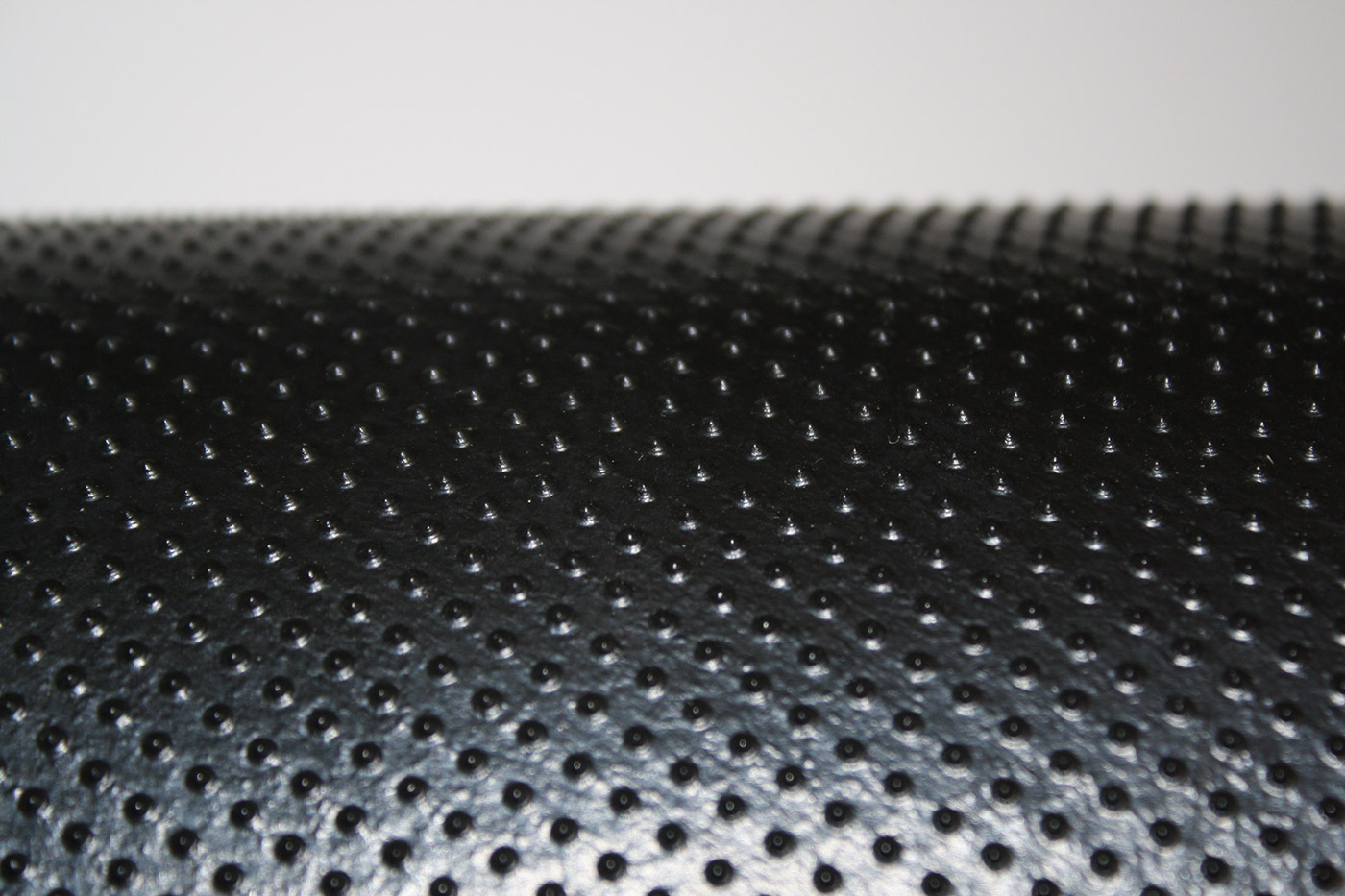

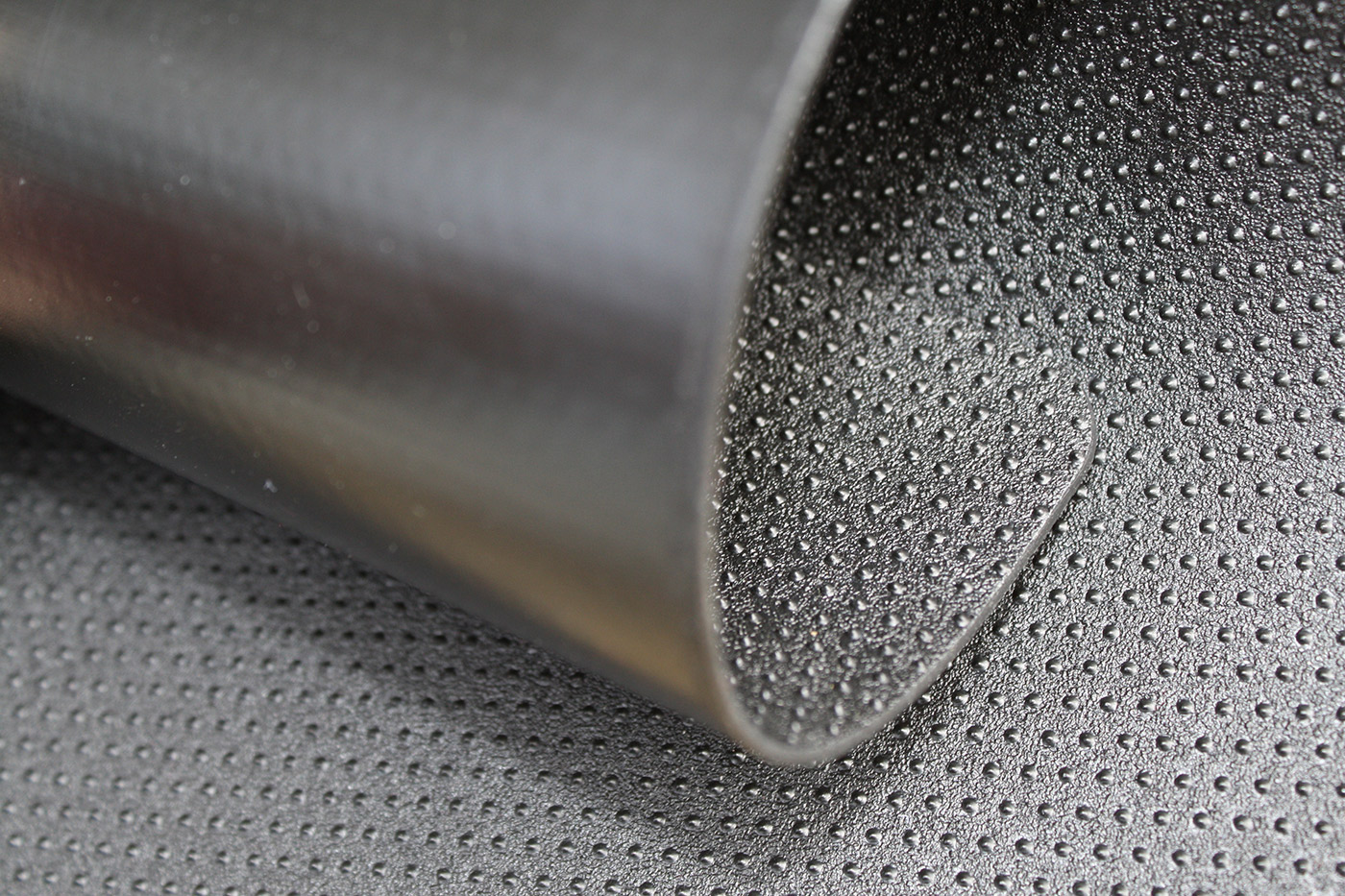

LLDPE

Atarfil LLDPE geomembranes combine flexibility and resistance, perfect for adapting to irregular terrain and complex conditions. They are ideal for agricultural and liquid containment applications, offering reliable and durable waterproofing.

PP

Atarfil PP geomembranes stand out for their flexibility and resistance to extreme weather and chemicals. They are perfect for long-term applications in tanks, reservoirs and industrial waste management, offering high durability and UV stability.

EVO Advanced GMB

Atarfil EVO geomembranes has gone beyond minimum specs including an antioxidant additive package which extends liner longterm performance in critical sites. Given to our Customers technical evidences such as presenting both HP OIT & Std OIT initial and final values after Oven Aging. A detailed proved screen to our EVO outstanding antioxidant package.

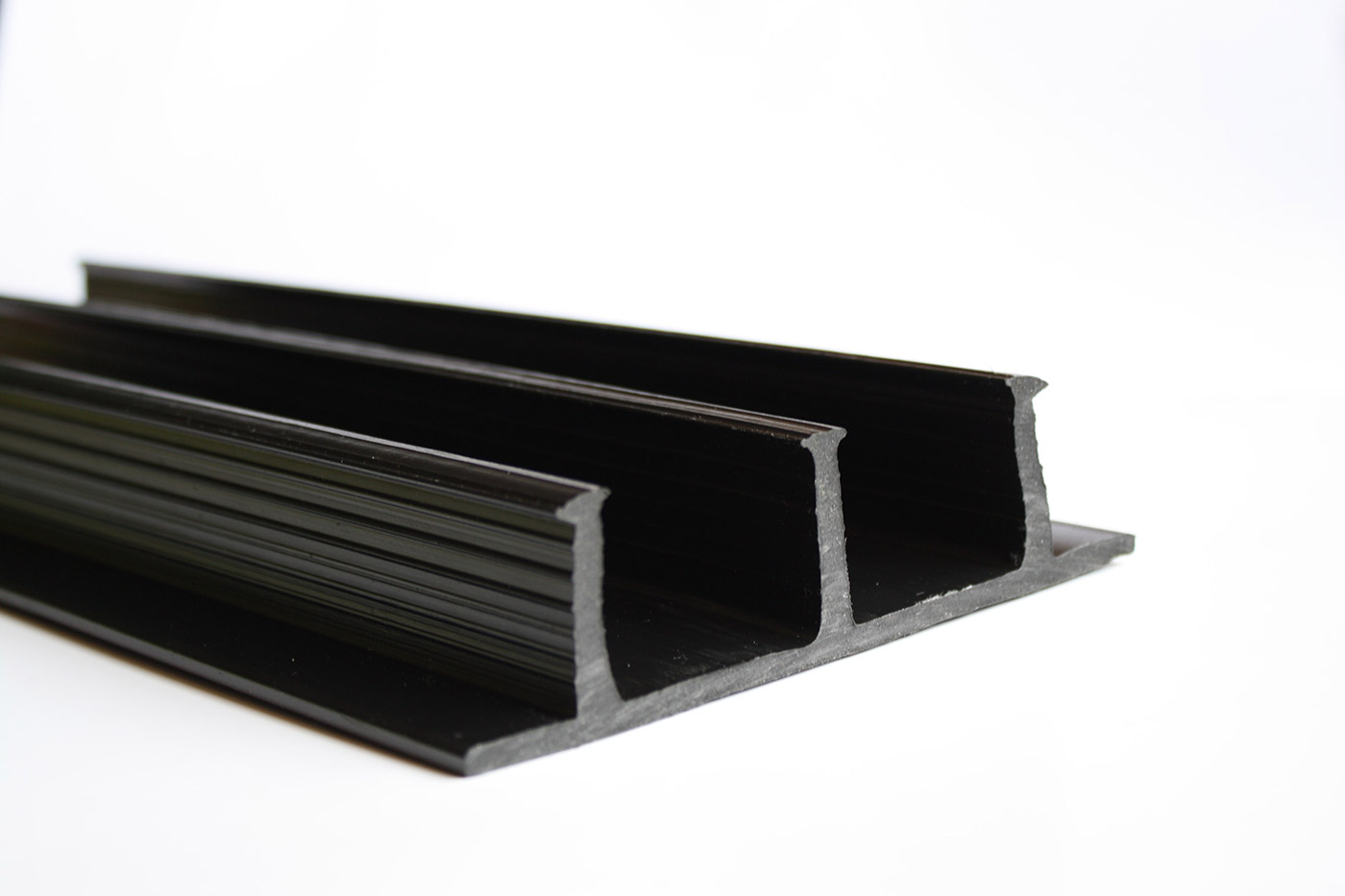

Complementary products

In this category we include profiles, welding wire and other essential accessories that ensure efficient installation and maximum performance of our geomembranes. These complementary products are designed to integrate seamlessly with our solutions, ensuring long-lasting and reliable protection on any project.

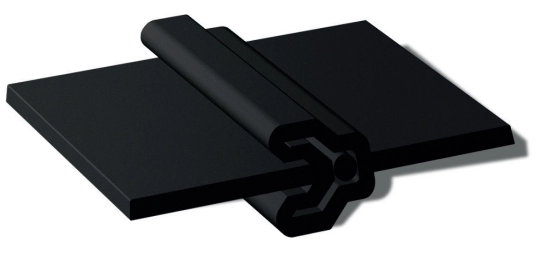

Systems

We provide complete waterproofing systems, from design to installation. Our integrated solutions are designed to meet the specific needs of each project, guaranteeing optimal and long-lasting performance.

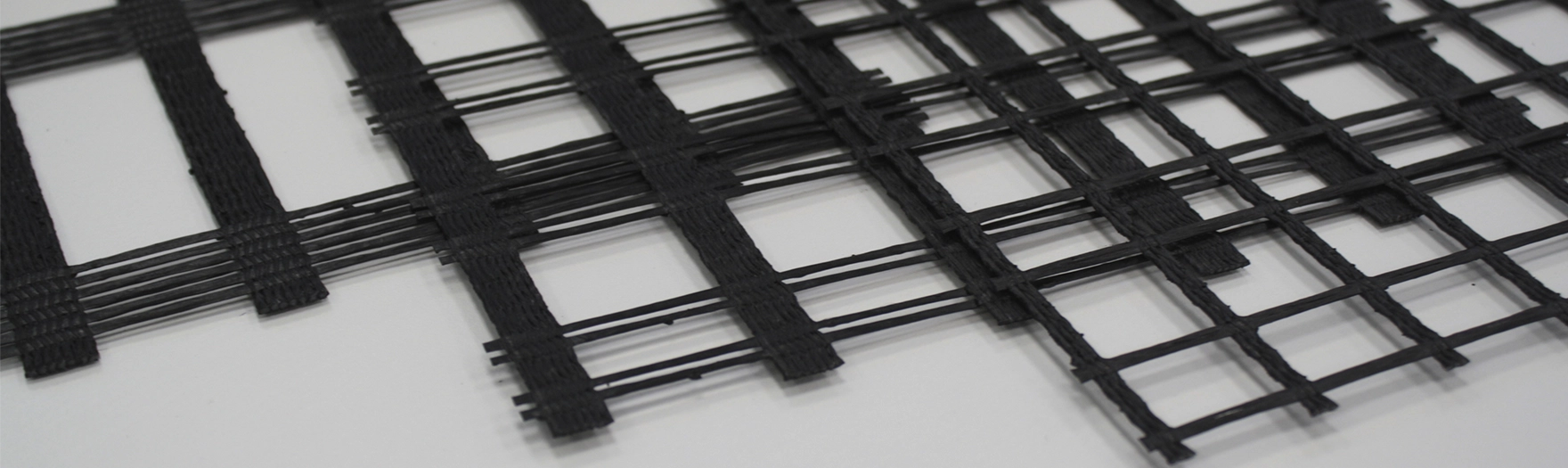

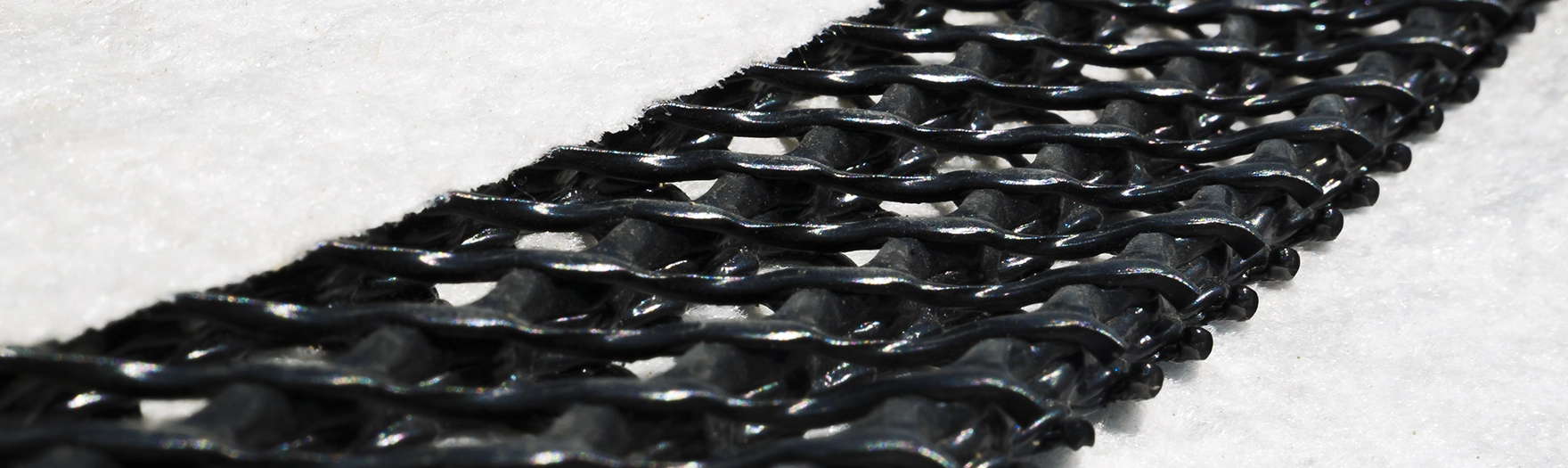

Other geosynthetics

Supply service of other types of geosynthetics, in order to offer a complete secure containment system. We work with high quality products that complement our solutions, guaranteeing optimum performance and meeting the requirements of each project.