Introduction

Atarfil’s base-level HDPE geomembrane (often marketed as Atarfil HD, “GRI GM13”-compliant) is engineered to deliver performance characteristics far exceeding the GM13 minimum requirements. While GM13 has historically been the baseline specification for HDPE liners, it no longer reflects the industry’s innovative advancements. Manufacturers who are committed to cost reduction and margin maximisation will often manipulate formulations to meet GM13, which inevitably leads to material performance loss over time. The focus has shifted from quality to a race to the bottom, where producers seek to meet only the bare minimum specifications to stay competitive.

As standards like GM13 remain static, manufacturers take advantage of loopholes by introducing resins and materials that meet the technical benchmarks but degrade faster in real-world applications. This trend inevitably results in more construction quality assurance (CQA) issues and unsatisfactory performance of geomembranes under real-world stresses.

Atarfil refuses to lower its standards to meet the outdated GM13 requirements because we believe that quality and durability should be the foundation of any containment solution. By maintaining superior specifications, Atarfil ensures that our geomembranes provide long-term, reliable performance. It’s a matter of prioritising longevity over cost-cutting. While GM13 may have once been an adequate specification, it no longer aligns with industry needs or the performance expectations of today’s high-risk containment projects. To safeguard project success and the integrity of containment systems, Atarfil continues to rely on premium materials, rigorous quality control, and proven resins that outperform the industry’s baseline standards.

Sticking to proven, reliable materials with higher specifications is the best way to guarantee long-term performance, reduce CQA issues, and ultimately protect the integrity of critical containment systems.

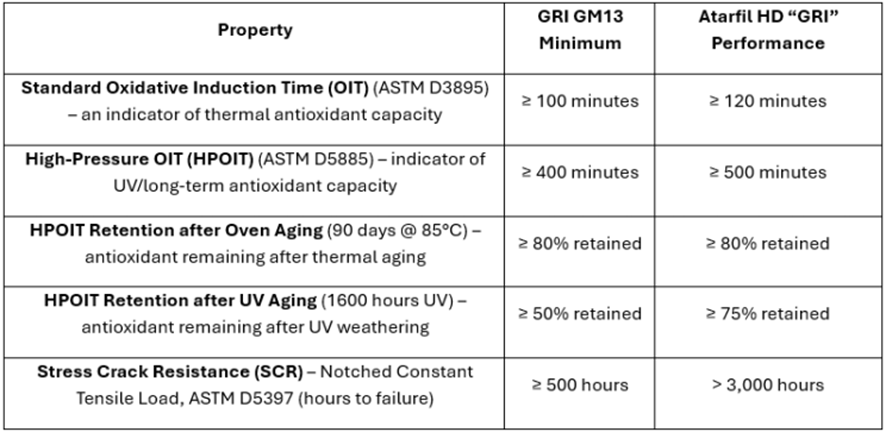

Atarfil HD vs GRI GM13 – Key Property Comparison

As shown above, Atarfil HD’s oxidation induction times (both standard OIT and high-pressure OIT) are included and are significantly higher than GM13’s baseline. It also retains more antioxidants after aging tests – e.g. ~75% HPOIT retention (in UV) versus the 50% required. Most strikingly, its stress crack resistance exceeds 3,000 hours, around six times the GM13 criterion. For installers, these numbers translate to a liner that is more robust against degradation during installation and over the liner’s service life. In practice, exceeding GM13 by such margins means added safety factor – the material can better withstand the stresses of handling, welding, and exposure before cover.

Beyond GM13: Installation-Focused Advantages

Beyond just meeting lab tests, Atarfil’s manufacturing and formulation provide practical benefits to installers that typical GM13-compliant products may lack. Key differentiators include:

Premium High-SCR Resin & Controlled Cooling Process: Atarfil HD is made from top-tier HDPE resins with inherently high stress-crack resistance, combined with an in-house flat-die extrusion (calendering) process. The flat-die method uses polished chill rolls to cool the sheet uniformly, yielding a very flat, low-stress geomembrane. The result is a liner with the highest SCR values in the industry – meaning it tolerates rough handling, point loads, and thermal stresses without developing stress cracks. For installers, this durability translates into reduced risk of damage during installation: the liner resists cracking if dragged over subgrade irregularities or when exposed to the heat of welding. The controlled cooling and superior resin minimise internal stresses, so the material can absorb scratches or deformation without brittle failure. In short, the liner’s toughness and surface abuse resistance give crews more forgiveness against accidental gouges or high welding temperatures.

Dual Antioxidant Package (OIT + HPOIT Performance): Unlike many standard HDPE geomembranes that optimise primarily for one oxidation test (often the high-pressure OIT for UV resistance), Atarfil HD uses a balanced antioxidant formulation to perform strongly in both the standard OIT and HPOIT tests. This “dual” antioxidant system combines primary antioxidants (phenolic and phosphite stabilisers) for long-term thermal oxidation protection (reflected in the standard OIT) with UV stabilisers like HALS for long-term UV resistance (reflected in the HPOIT). The result is a geomembrane that protects against heat oxidation and UV weathering simultaneously. For the installer, this means the material is less likely to degrade or embrittle from on-site stressors – heat from welding, prolonged sun exposure prior to covering, or even stockpile storage. Atarfil’s liner has a more comprehensive antioxidant defence, whereas a typical GM13 liner might meet the spec by excelling in HPOIT alone (UV resistance) but could have lower standard OIT (thermal and chemical stability). Atarfil’s approach ensures no compromise: the geomembrane maintains stability during installation (when thermal oxidation can occur from welding or high ambient temperatures) and during any exposed service life under UV.

Flat-Die Extrusion = Superior Flatness, Thickness Uniformity & Weldability: Atarfil manufactures its sheets by flat-die extrusion (also called flat-sheet calendaring), rather than the blown-film process used by some other geomembrane producers. Flat-die production achieves tighter thickness control and a flatter sheet across the roll width. This has tangible benefits in the field: the liner unrolls smoothly without curled edges or camber, and exhibits minimal variability in thickness. Consistent thickness ensures that wedge welding and extrusion seaming can be performed at uniform speed and heat settings – reducing the chance of thin spots that could burn through or thick spots that might cold-weld. Installers find flat-die geomembranes easier to handle and sear: the material lies flat against the subgrade, which aids panel alignment and eliminates excessive bridging or wrinkles during placement. Moreover, Atarfil’s flat-die process supports its structured texturing method (for textured products) without sacrificing sheet integrity. The textured version of Atarfil HD uses a structured pattern of asperities (cones) that is applied in-line, yielding a very uniform roughness profile. This means high friction for slope stability, yet the texture is consistent and does not significantly reduce tensile or elongation properties. (Atarfil specifically notes that their texturing maintains excellent elongation at break.) For installers, uniform texture and flatness make for more reliable seaming – the edges of the rolls are produced smooth for welding strips, and there are no extreme variations in texture height that could interfere with seam pressure. In summary, the flat-die manufacturing yields a liner that is flat, dimensionally stable, and consistently textured, simplifying installation and ensuring high-quality welds.

Higher Allowable Strain Tolerance (6% vs 4%) – Reduced Stress Crack Risk: Industry research on HDPE liners (notably by Dr. Ian D. Peggs and others) has shown that excessive tensile strain in service can lead to stress cracking over time. Traditional guidance often limits textured HDPE liners to ~4% strain to prevent long-term crack development, whereas smooth liners (or very high-SCR materials) might tolerate ~6–8% strain safely. Atarfil’s HD geomembrane, with its exceptionally high stress crack resistance (>3000 hours), provides a greater safety margin against strain-induced cracking. In practical terms, this means the liner can accommodate more movement or deformation before cracks initiate. For example, differential settlement of subgrade or point loads that cause the liner to stretch locally are less likely to compromise Atarfil HD compared to a standard liner. Peggs et al. (2005) recommended ~6–8% as an allowable tensile strain for high-SCR/smooth geomembranes, versus ~4% for conventional textured ones. Atarfil’s material falls in the higher tier – installers can have confidence that the liner will tolerate moderate strains (on the order of 6%) without failure, provided proper engineering design. This higher strain tolerance is particularly relevant for textured applications on slopes or irregular subgrades: the liner can conform more without cracking. It acts as an added buffer during installation – e.g. if slight stretching occurs when panels are positioned or if minor slack needs to be pulled out, the risk of inducing stress cracks is lower. Ultimately, the combination of premium resin and superior SCR performance in Atarfil HD means less worry about brittle failure even if the liner experiences strains beyond the conservative 3–4% often cited for standard HDPE.

Conclusion

Atarfil HD geomembrane elevates the baseline for HDPE liner performance, marrying credible technical enhancements with practical benefits for installation crews. In direct comparison to GRI GM13 requirements, it offers far longer oxidative induction times, greater antioxidant retention after aging, and dramatically higher resistance to stress cracking – all indicators of a more durable, long-lived material.

More importantly for installers, these properties are delivered through manufacturing and formulation choices that improve on-site workability and reliability. The flat-die extrusion process ensures a liner that is flat and uniform, making layout and welding easier and more dependable. The use of a dual antioxidant package and high-SCR polymer means the material can withstand the rigours of installation (heat, UV exposure, handling) without premature degradation. And the superior strain tolerance provides peace of mind that the liner won’t crack under reasonable strains from subgrade settlement or thermal expansion.

In avoiding marketing hyperbole, the facts speak for themselves: Atarfil’s HD liner is engineered for consistency and toughness. Installers can expect fewer hassles – fewer repairs from accidental damage, stronger seams, and a liner that remains robust from deployment to long after cover. By focusing on these technical differentiators, Atarfil HD offers a practical advantage: a safer and more installer-friendly geomembrane that ultimately contributes to the long-term success of containment projects.