Project Details

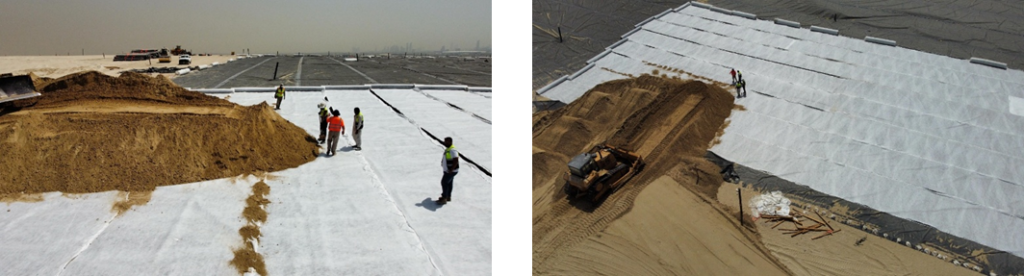

The project involved the installation of a landfill gas extraction and treatment network across an area of 426,075 m², improving landfill operations while supporting Dubai’s strategy of circular economy and energy recovery from waste.

It is the first landfill in the UAE to implement such a system, setting a milestone in sustainable waste management in the region. The project supports Dubai’s waste-to-energy strategy, reducing emissions and creating positive environmental outcomes. The combination of reliable technology, efficient logistics, and close technical support was critical to success.

Beyond contributing to waste-to-energy goals, the project carried a unique aspect: it was led by women engineers and managers, highlighting the value of diversity and female leadership in environmental infrastructure initiatives.

This project opens doors to further collaboration with Dubai Municipality and future initiatives in waste management and renewable energy.

With this project, Atarfil not only delivered high-quality technical solutions but also contributed to a pioneering achievement in sustainability and diversity in the UAE.

Materials were selected according to consultant design and international regulatory standards. Atarfil was selected over other geomembrane manufacturers thanks to the reliability of its products, strong technical support, and on-time delivery performance. Reason for Selection: optimal balance of durability, performance, and cost efficiency. Although a 1.50 mm thickness was considered, the 1.00 mm option was chosen to reduce costs without compromising functionality. The main challenge was the tight project timeline, requiring high-quality materials, efficient logistics, and responsive technical assistance.

Client satisfaction: The client praised both the quality of Atarfil products and the close technical and commercial support, including a factory visit to Spain that reinforced trust in the brand.

On-time delivery: Materials were delivered on schedule, with consistent follow-up throughout the installation.

Differentiation: Atarfil stood out by offering responsive technical expertise, customer service, and reliability against competing manufacturers.

- GMB LLD TMT 1,00 mm B/B E 7,5×130 GRI (426,075 m²)

- Non-woven PP geotextile, 180 g/m².

- Drainage geocomposite.

Atarfil did not participate in the design phase, but provided on-site visits, ensuring compliance with standards and assisting with client inquiries.

Installation was completed on schedule.

Quality control:

- In-house Atarfil testing.

- Third-party testing at BICS UK.

- On-site verification: air pressure, vacuum box, peel and shear tests with tensiometers.