Project Details

In recent years, agricultural operations have been seeking solutions to reduce emissions from their waste ponds, especially slurry ponds. This need has been driven by changes in the European regulatory framework aimed at reducing greenhouse gas and ammonia emissions.

Pig slurry, which is a mixture of feces, urine, and cleaning water, emits several gases during its storage and treatment. The main gases emitted are:

- Ammonia (NH3): Results from the decomposition of urea present in urine. It is an irritating gas that can affect human health and contribute to soil and water acidification.

- Methane (CH4): Produced during the anaerobic decomposition of organic matter in slurry. It is a potent greenhouse gas with a much greater global warming potential than carbon dioxide.

- Nitrogen oxides (NOx): Include nitric oxide (NO) and nitrogen dioxide (NO2), which can form during the decomposition of nitrogen compounds. These gases contribute to the formation of tropospheric ozone and acid rain.

- Hydrogen sulfide (H2S): Generated during the anaerobic decomposition of sulfur compounds. It is a toxic and foul-smelling gas that can be hazardous to health at high concentrations.

- Carbon dioxide (CO2): Produced under both aerobic and anaerobic conditions during the decomposition of organic matter. Although less potent than methane, it contributes to the greenhouse effect.

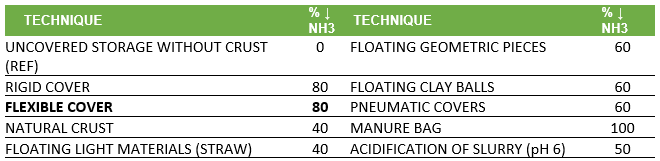

Proper management of pig slurry includes techniques to reduce these emissions, such as covering the ponds and storage tanks. The use of flexible covers helps reduce emissions by approximately 80%, as outlined in best practice guidelines.

Effect of pig and bovine manure storage on ammonia emissions, reduction of NH3 compared to the reference technique. (Source: Guide to the Best Available Techniques for Reducing the Environmental Impact of Livestock – MINISTRY OF AGRICULTURE, FISHERIES, FOOD, AND ENVIRONMENT OF SPAIN)

Solution

Atarfil has developed a polyethylene geomembrane that meets the requirements and demands of this application. Along with auxiliary systems, it forms a cover system capable of adapting to different levels of exploitation. This system is complemented by aerators that facilitate the evacuation of air and gases accumulated beneath the cover, as well as pumps that ensure proper drainage of rainwater

ATARCOVER is a co-extruded bicolor geomembrane, manufactured with 100% virgin polyethylene resins using the most advanced flat-die calendaring technology developed in-house. The result is a uniform product with high performance, durability, and long-term efficiency

Specifically designed to offer excellent mechanical properties, UV resistance, flexibility, and weldability, its properties and high performance make ATARCOVER the ideal solution for floating covers.

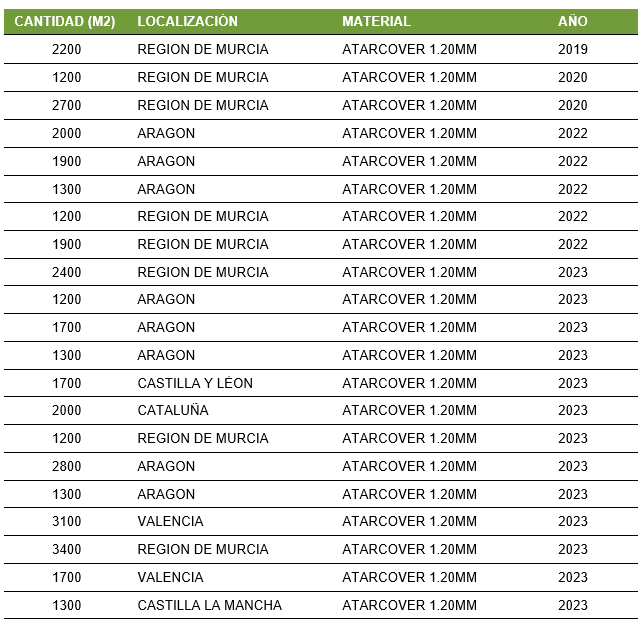

Projects Details